Tesolar

150-750W Solar Pump DC 12/24/48/60V Water/ Solar Pump With Built-in Controller For Agriculture

150-750W Solar Pump DC 12/24/48/60V Water/ Solar Pump With Built-in Controller For Agriculture

Couldn't load pickup availability

CE

CE

FCC

FCC

ROHS

ROHS

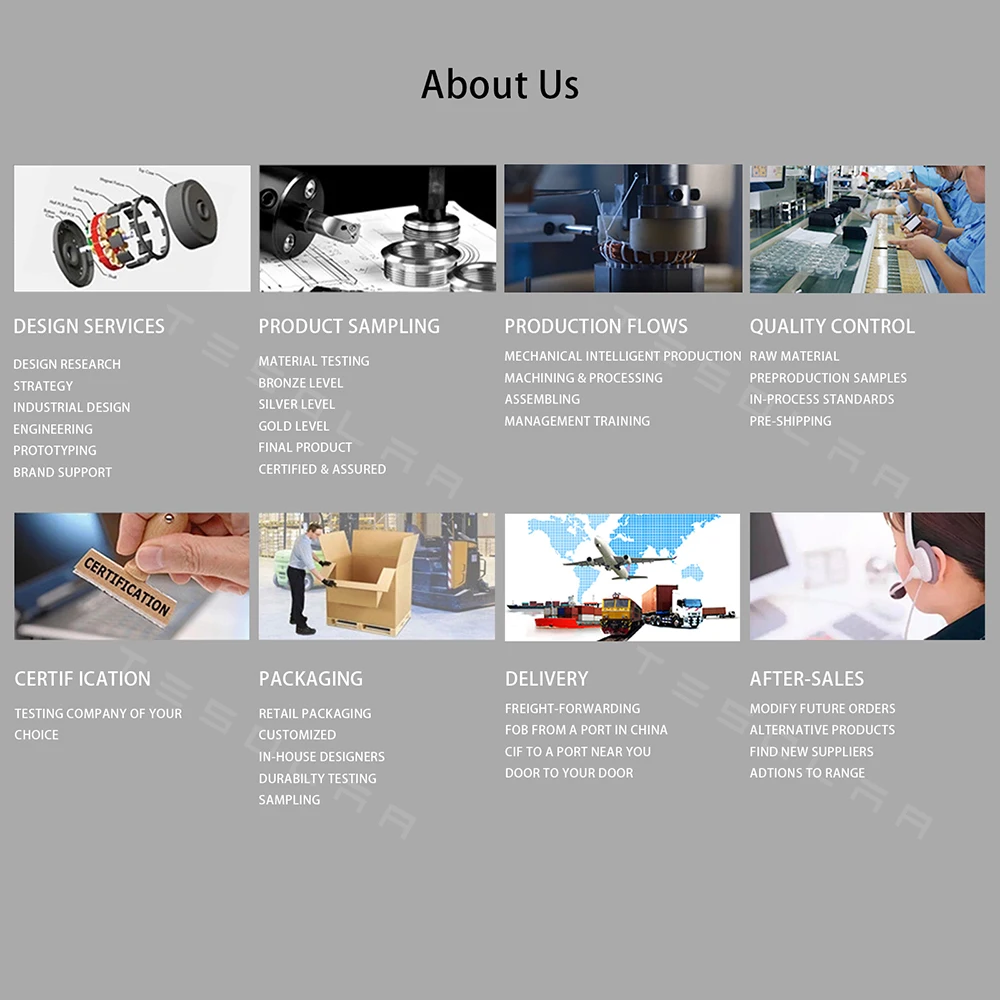

SPECIFICATIONS

Brand Name: VESDAS

Structure: Submersible Well Pump

Power: Electric

Fuel: Electric

Usage: Water

Model Number: 3SP2

Application: Submersible

Standard or Nonstandard: Standard

Outlet: 2.54 cm

Outer: 25 MM

Impeller: Screw

About Product DC pump

Solar DC brush-less pumps is powered by brush-less direct-current motor. The solar panel directly supplies power and automatically starts and stops. Equipped with complete electric protection system such as low voltage, high voltage, overload, overheat, jam protections and special water-proof seal as well as advanced cast iron, stainless steel etc.

The pump is gifted with superior characters: energy-saving, large flow rate, anti-rust. Whats\’s more, as it's compact structure, modern design, convenient operation and maintenance. Solar DC brush-less series pumps is ideal for fields as agriculture, deep well water, house etc.

|

Bilt-in controller Solar DC Screw deep well Pump |

||||||||

|

Technical data |

||||||||

|

NO. |

Model |

Pump |

Max Flow |

Max Head |

Outlet |

Outer |

||

|

Impeller |

Power |

Voltage |

(M3/H) |

(M) |

(IN) |

(MM) |

||

|

1 |

3SP2-35-D12-150BI |

Screw |

200 |

DC12V |

2 |

35 |

1" |

25 |

|

2 |

3SP2-65-D24-370BI |

Screw |

370 |

DC24V |

2 |

65 |

1" |

25 |

|

3 |

3S1.3-50-D24-140BI |

Screw |

140 |

DC24V |

1.3 |

50 |

0.75" |

76 |

|

4 |

3S1.6-80-D36-210LBI |

Screw |

210 |

DC36V |

1.6 |

80 |

0.75" |

76 |

|

5 |

3SP2-100-D4860-750BI |

Screw |

750 |

DC48-60V |

2 |

100 |

1" |

25 |

|

6 |

3S1.8-100-D48-400BI |

Screw |

400 |

DC48V |

1.8 |

100 |

0.75" |

76 |

|

7 |

4S3.0-60-D48-500BI |

Screw |

500 |

DC48V |

3 |

60 |

1" |

96 |

|

8 |

4S3.6-80-D48-750BI |

Screw |

750 |

DC48V |

3.6 |

80 |

1" |

96 |

|

Solar &. Voltage matching table |

|

||||||||

|

NO. |

Model |

Pump |

Recommend Solar |

12V Battery |

|||||

|

W |

DC |

Solar Panel |

Series |

Vmp |

Solar QTY |

Voc |

Series |

||

|

1 |

3SP2-35-D12-150BI |

200 |

DC12V |

200-300W |

2*1PCS |

1*18V |

2 PCS |

<32V |

1*1 PCS |

|

2 |

3SP2-65-D24-370BI |

370 |

DC24V |

500-750W |

1*2PCS |

2*30V |

2 PCS |

<72V |

1*2 PCS |

|

3 |

3S1.3-50-D24-140BI |

140 |

DC24V |

200-300W |

1*1PCS |

1*36V |

1 PCS |

<44V |

1*2 PCS |

|

4 |

3S1.6-80-D36-210LBI |

210 |

DC36V |

300-450W |

1*2PCS |

2*24V |

2 PCS |

<60V |

1*3 PCS |

|

5 |

3SP2-100-D4860-750BI |

750 |

DC48-60V |

1000-1500W |

2*2PCS |

2*30V |

2 PCS |

<72V |

1*(4-5)PC |

|

6 |

3S1.8-100-D48-400BI |

400 |

DC48V |

500-800W |

2*2PCS |

2*36V |

2 PCS |

<96V |

1*4 PCS |

|

7 |

4S3.0-60-D48-500BI |

500 |

48V |

700-720W |

1*3 PCS |

3*24V |

3 PCS |

<100V |

1*4 PCS |

|

8 |

4S3.6-80-D48-750BI |

750 |

48V |

1050W |

2*2 PCS |

2*36V |

4 PCS |

<100V |

1*4 PCS |

About solar panel

Generally, the power of a solar panel of 1 square meter is about 150W. Actually, after passing through the solar energy system, the output is about 108W, which means that it can be used around 108W. The efficiency of the system is generally about 65%, and the highest is 70%. The power generation efficiency is related to many factors such as peak sunshine, installation angle, and ambient temperature. From 9:00 am, 10:00, 11:00, the power generation efficiency is 30%. 45%, 60% up to 70% at 12 noon, and slowly down 60%, 50%, 40% in the afternoon, from 4 to 30% in the afternoon. The solar panel calculated by dividing the pump power by 70% can only have 3 to 4 hours of rated power required for the work, and the rest of the time does not meet the rated working requirements of the pump. operating hours. If the electricity consumption is divided by the power generation efficiency by 50%, the pump can be rated for 6 hours a day and 8 hours a day.

The power of the solar pump generally refers to the power required for the maximum electricity consumption. It refers to the input power of the pump, which is different from the power of other pumps. The power of other pumps is the rated power of the pump (refers to the output power of the motor). To have an efficiency is the efficiency of the motor. Under the premise of requiring the same power, the efficiency of the permanent magnet synchronous motor is high, and the solar panels used are less. In the pump selection of solar panel power, the first step is to determine the power consumption of the pump, that is, the pump input power is determined, and then divide by the solar panel's power generation efficiency of 65% (up to 70%) or multiplied by 1.5, the result is The nominal power of the solar panels that need to be supplied to the pump. Based on the power of this solar panel, the number of solar panels to be used with how much power and how much power is used is calculated.

Share

Product Q&A

How to properly configure solar panels for pumps ?

The configuration of A reasonable solar panel for the pump mainly considers two parameters:

Power & voltage. Relative to the pump power, you can configure the solar panel by 1.5-2 times.

For example: If the rated power of pump is 200W, then install 300-400W solar panel is workable. If the power of the solar panel is much larger than 2 times the pump power, the pump can still work normally as long as the output voltage of the solar panel is within the safe range.